Toll Processing

Alanod-Westlake is a toll processing manufacturer specializing in supplying sheets and blanks to various industries including but not limited to the lighting, automotive, architectural, and solar industries.

As a toll processor, we manufacture custom and standard high-quality slit coil and blanks. The materials can either be supplied by our customers or we can use our expansive connections to help source the best materials for your specific project.

Most of our customers are OEMs and service centers who come to us for our expertise and extensive capabilities. Typically, we provide them with aid in smaller runs and difficult jobs that they cannot do in-house. No job is too large or too small.

Why Use Alanod-Westlake Metals as Your Toll Processor?

There are many benefits of working with Alanod-Westlake Metals (AWMI) as your critical surface metal processor. When working with us, you receive cost-effective services including 100% quality inspection, tight tolerances, and superior packaging from our experts on their lines.

There are many benefits of working with Alanod-Westlake Metals (AWMI) as your critical surface metal processor. When working with us, you receive cost-effective services including 100% quality inspection, tight tolerances, and superior packaging from our experts on their lines.

Multi-Blanking Lines

Each of our lines are run by team members who have many years of experience running, supervising, and perfecting their processes. They know their machines and our customer's requirements inside and out.

Cut-to-Length Lines

Both of our cut-to-length lines have multi-blanking “slear” (slitting and shearing in a single pass) capabilities up to five cuts.

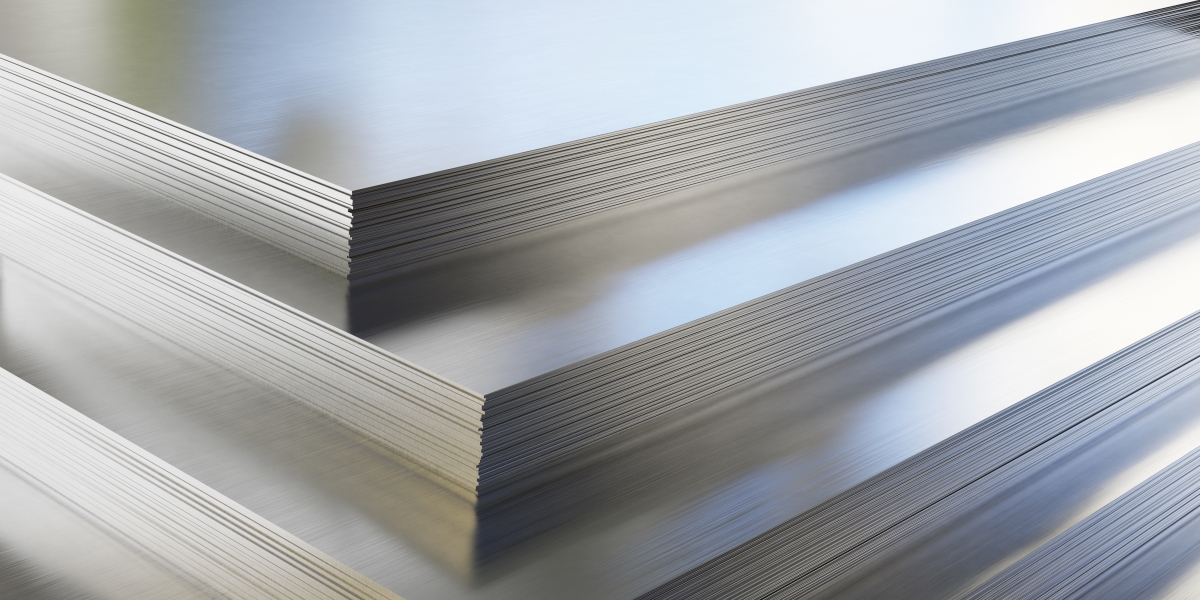

Variety of Tight Tolerance Blanks and Sheets

We can process blanks and sheets anywhere from four inches to 40 feet in length. We always try to accommodate requests outside of our current capabilities, so don't hesitate to ask!

In addition, many of our customers do not have the in-house capabilities to process their own metals for their end products. Whether you lack the manpower, expertise, machinery, physical space, or the time to process your metal yourself, we can help. When these shortfalls impact your quality or productivity, contact us to talk more about what we can do for you.

Other Benefits of Working with Alanod-Westlake:

- Custom product development and R&D

- Premium products with white-glove treatment when required. (Literally)

- We serve as our customer's quality department by providing 100% inspection.

- Adjustable production volumes based on demand

- Quick turnaround times

- We can add strippable PVC masking; we can also remove masking or paper interleaving

- Protective poly-vinyl film can be applied to one or both sides of the products

- We stock a variety of films as each metal requires its own type of adhesive.

- Superior custom packaging and crating for domestic and export shipping.

- Our high-quality packaging materials allow us to ensure the safe delivery of your valuable metals scratch and smudge-free!

Sheeting and Blanking

Each can add or remove strippable film or paper interleaving.

60″ Slear Specifications:

Incoming Coils

Core ID 20-24”

Max OD 72”

Max Weight 14,000 lbs.

Gauge Range

Aluminum - .012-.080

Stainless - .012 - .036

Sleared Cuts

Max -6

Tolerances

*Width Min – 4” (+/- .015)

*Length – 10”-144” (+/- .032)

48″ Slear Specifications:

Incoming Coils

Core ID 16-24”

Max OD 72”

Max Weight 10,000 lbs.

Gauge Range

Aluminum - .008-.063

Stainless - .008 -.024

Sleared Cuts

Max - 5

Tolerances

*Width Min – 3” (+/- .015)

*Length- 5”-144” (+/- .032)

*Narrower Widths / Longer Lengths Subject to Special Inquiry

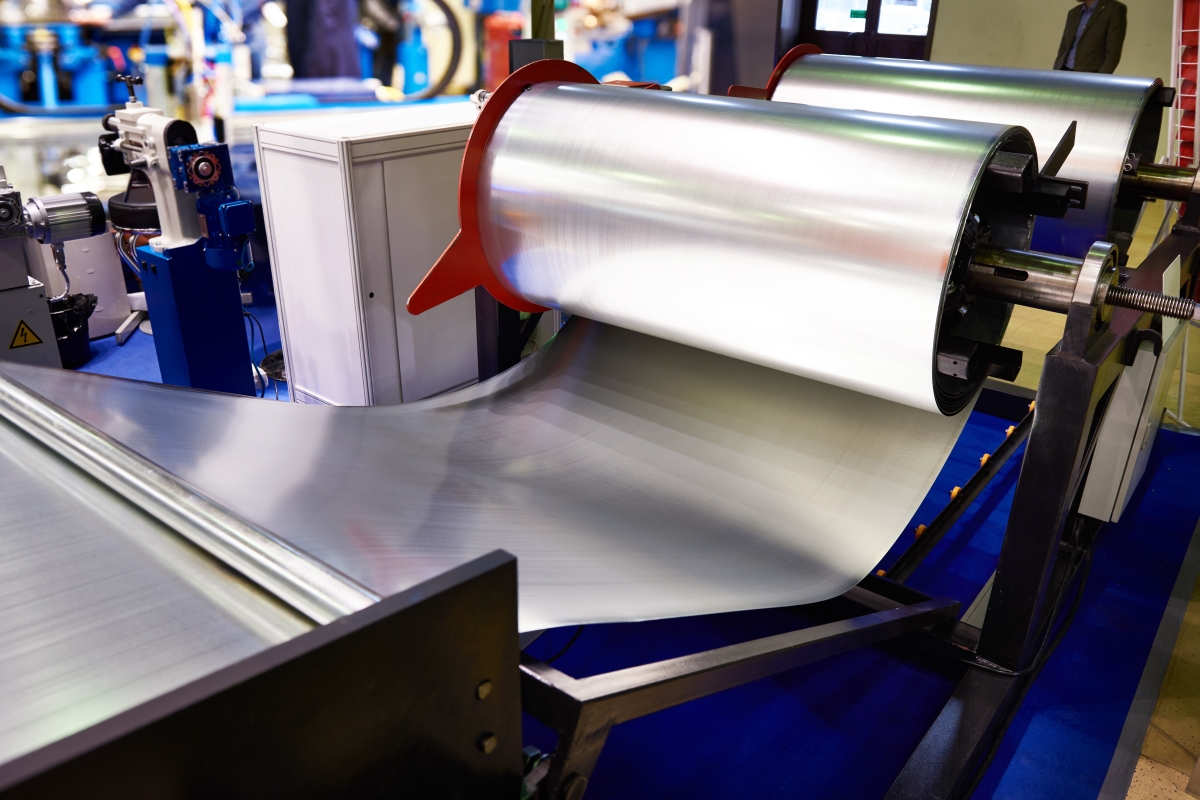

Coil-to-Coil Slitting

Coil-to-Coil Slitting

We specialize in slitting surface critical materials. We can add strippable PVC masking; we can also remove masking or paper interleaving.

52″ Light Gauge Looping-Pit Slitter:

Capabilities

Minimum 1” to Maximum 52”

16 cut per-pass capability

Film Application 1 or 2 sides

Width tolerances of +/- .005 Guaranteed

Gauge Range

Aluminum - .008 - .080

Stainless .006 - .043

Incoming Coils

Core ID 16”-24”

Max OD – 72”

Max Coil Weight 14,000 lbs.

Toll Processing by Material

Aluminum Toll Processing

We offer sheeting and blanking, and coil slitting services for custom dimensions for your aluminum needs.

Stainless Steel Toll Processing

We offer sheeting and blanking, and coil slitting services for custom dimensions for your stainless steel needs.

Titanium Toll Processing

We offer sheeting and blanking, and coil slitting services for custom dimensions for your titanium needs.

Coated Steel Toll Processing

We offer sheeting and blanking, and coil slitting services for custom dimensions for your coated steel needs.