Alanod Lighting

Benefits of Reflective Metals

Light Quality through Durability

Our reflective surfaces are perfect for LED lighting systems, providing consistently high-performance reflectivity over the life of an LED bulb (about 50,000 hours) and longer, with no reflection loss or color distortion.

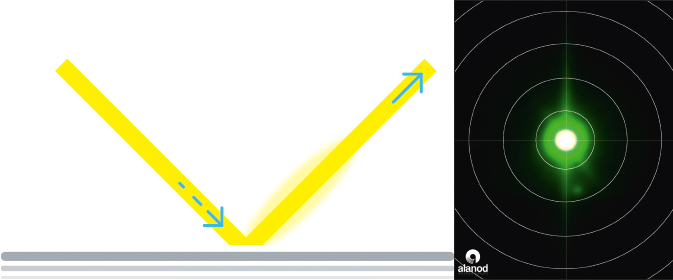

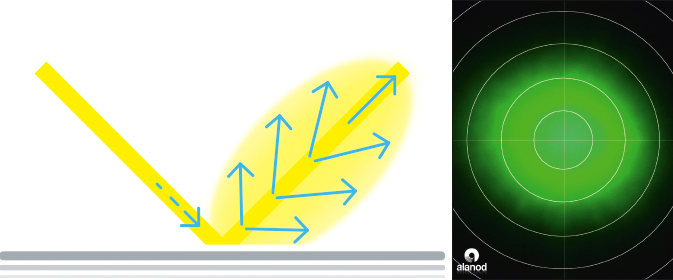

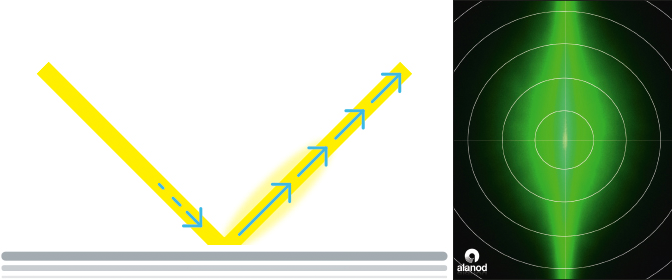

Light Quality through Light Control

Light control and light quality go hand in hand, regardless of your application's requirements, our products offer ideal results. Whether you need isotropic or anisotropic reflection characteristics, darklight effects, or ergonomic self-luminance, we have a wide range of products to suit your end-goal.

We have the right surfaces for:

- Directing light precisely – for example:

- for downlights or spotlights in shop lighting

- for industrial lighting at great heights (e.g. MIRO® 27)

- Directing light diffusely – for example:

- for streetlights and industrial lighting at a lower height.

- Our materials allow individual LED light points to be dissipated, thus achieving smooth light distribution (e.g. MIRO® 20)

- Distributing light linearly through one surface alone – the point becomes a line. In offices or industry, linear lights are far superior to rotationally symmetrical solutions in terms of workplace ergonomics (e.g. MIRO® 5/5013GP)

Light Quality through Glare Limitation

The high performance of modern LED technology has once again shifted focus onto the issue of glare. Correct control of light by means of reflectors contributes to the avoidance of direct glare and allows for a precise intensity distribution curve.

High-Quality Look

Our aluminum qualities stand out not only with their excellent reflective properties but also with the high-quality appearance of their metallic surface. This gives modern light and reflector designs unique quality and value.

Simple Processing

Special lighting concepts require special reflective materials. Surfaces for lighting technology are frequently being formed three-dimensionally using techniques such as pressing, deep drawing, or hydroforming. These methods can also be combined with the segmentation of reflectors. We offer suitable qualities for this in terms of strength properties.

Request a Quote

Interested in getting started with Alanod-Westlake? Request a quote today!